[wpseo_breadcrumb]

PTFE Slide Bearings & PTFE Expansion Bearings

Introduction

Armadillo can design and manufacture PTFE Launch Bearings, PTFE slide structural bearings, PTFE skid pads, PTFE Structural Bearings, Dimpled PTFE and Glass Filled PTFE or Glass filled PTFE and dimpled PTFE, PTFE skid pads, Pipe slides and PTFE pipe saddles, Heavy Duty skid pads and heavy load PTFE slide bearings.

There are many applications in industry where relative movement between two surfaces must be accommodated.

These applications call for high load capacity at low speed, meaning self lubricating PTFE is an ideal material to be employed. Armadillo NV have a vast experience in designing and supplying custom made expansion bearings to address this issue.

Product Advantages

- Simple construction gives cost effective solutions to the problem.

- Even for small production runs bearings can be very cost effective.

- PTFE is self lubricating, and can even absorb some dirt particles into the bearing surface offering unrivalled lifetime performance.

- Friction values are 6% down to less than 2% depending on working stress. (The higher the load the lower the value)

- Can be designed to accommodate high temperature applications.

- Indefinite life because weather elements, and many chemicals have little effect on PTFE. Moisture absorption is low.PTFE is chemically inert.

- Maintenance free, PTFE can not cold weld so needs no lubrication.

- PTFE Bearings are a lower profile than many alternative assemblies, saving space.

- Galvanic corrosion is eliminated due to the high electrical and thermal insulation properties.

Product Description

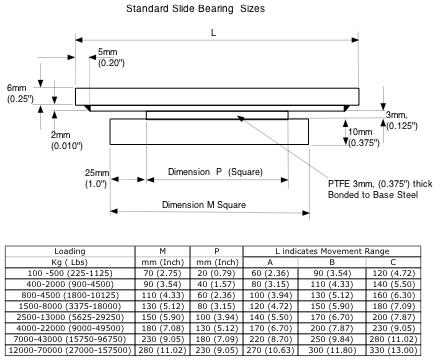

Armadillo Expansion Bearings and Slide Bearings consist of a 3 mm thick virgin PTFE bearing face element bonded or, in some applications recessed into a carbon steel base plate. Standard thickness would be 10mm although thicker plates can be supplied. This is refereed to as the Base Element.

Sliding above this assembly is a 1 mm thick polished Stainless Steel slide plate which is either epoxy bonded or tack welded to a 6 mm thick carbon steel top plate, (other thickness’ available on request). The SS plate is of a sufficient area to always completely cover the PTFE bearing face. This effectively seals the slide surface from dirt ensuring an exceptional life expectancy of the unit.

In critical applications there may be thermal considerations or excessive vibration, shock or rotation to be accommodated. In this event, Armadillo can offer a range of load bearing products to be incorporated into the design.

Coefficient of Friction

Typical friction values have been measured between 10% down to as low as 2%. A key factor in selecting PTFE as the sliding medium is the exceptionally small difference between static and dynamic friction, this gives the added benefit of very low, “stick-slip” differences, ensuring a smooth transition in operation.

Bonding of the Bearings

All bonding of the PTFE is carried out under strictly controlled factory conditions, it is therefore not recommended to attempt to Bond the PTFE on site. Attaching the upper and lower elements to the structure can be achieved by either site welding or mechanical fixings. For further details, contact Armadillo Engineering Department.

PTFE Thickness

Standard supply is 3 mm thick Virgin PTFE, this has been found to give an adequate bearing life. If the PTFE is to be recessed into the base steel, thickness may be increased to 5 mm. For exceptionally high bearing loads, glass filled PTFE would be supplied.

Bearing Dimensions

The Base Unit dimension are dependant on, load the unit will be exposed to, physical size restraints of the installation location and in some cases if there is any rotation to be accommodated.

It is typical, although not compulsory that the sliding takes place across the short access of the bearing. This is also the case in accommodating any rotational issues.

Bearing Temperature

Temperature at the bearing surface should be limited to less than 120°C, in the event of the application requiring a higher operating temperature contact Armadillo Engineering department.

Design Steps

- Calculate load to be supported. This will give the total bearing area required.

- Decide on number of supporting locations for the structure.

- Consider any thermal , rotational or shock loading issues.

- Consider how the bearing assemblies will be installed, and fastened into position.

Applications

Slide Bearings

Armadillo structural slide bearings are custom designed to accommodate expansion, contraction and other reciprocating motions of any structure that moves as a result of thermal, seismic or differential forces.

Floor Vibration Isolation

Floor vibrations can be caused by walking, dancing, jumping, aerobics and other occupant activities. Mechanical equipment such as heating, ventilating and HVAC systems as well as pumps andin mechanical rooms can also cause floor vibrations. The basic configuration of a floor system should be established early in the design process.

Building Vibration Isolation

Train, traffic or subway generated ground waves can create structural vibration in a building’s foundations and base slab. The effect of this structural vibration is dependant on many factors including but not limited to the stiffness or rigidity of the building foundation, soil dynamics and the amplitude and frequency of vibration.

Machine Vibration Isolation

Load Bearing Pads

Foundation Isolation

See our comprehensive range of foundation isolation materials here.

Dance Floor Pads

Sports floors, gymnasiums and dance studios require a firm yet resilient feel. This is achieved by supporting the floor on resilient pads to give the correct balance for shock absorbing coupled with sufficient rebound to give the floor a “live” feel. Armadillo DFP15 is the ideal material to achieve this.

Pipe Support Bearings

A new range of bronze bearing plates supplied by Armadillo. These are used for numerous applications within pipeline support systems such as Oil & Gas to Industrial systems.

Materials

PTFE

When movements need to be accommodated in structural connections, a sliding element will need to be employed in the design. Armadillo can design manufacture and supply a cost effective solution for applications such as vessel thermal, petrochemical applications, pipelines or building movement joints. A PTFE surface is applied to Armaload fabric reinforced or ROF bearing pads where higher loads and rotation may occur.

Armaload - DLW66

Armaload DLW66 random oriented fiber (ROF) bearing pads are made from masticated elastomer which is fully cured and fiber reinforced. The random fiber reinforcement provides higher tensile and compressive strength, stiffness, tear resistance and durability than unreinforced rubber pads. ROF bearing pads will support loads up to 2,000 psi before breakdown.

Armaload - Mil-C-882

Armaload is a preformed fabric bearing pad which meets MIL-C-882, AASHTO 14.7.6.1, AASHTO 14.7.6.2 and AASHTO 18.10.1 specifications. Manufactured from compressed layers of closely woven lightweight fabric, bound withmaterial will support loads up to 12,000 psi before breakdown.

Armacork

Offered in various sheet sizes and thicknesses Armacork is the ideal entry level material to offer a cost effective and fast vibration control solution for many industrial applications.

The introduction of Armacork between the machine base and the supporting foundation effectively prevents the transmission of structure borne disturbance to the adjacent areas.

Neoprene / Rubber Pads

Some applications do not warrant the expense of a custom made Vibration Control pad but do require some element of resilience in the installation.

In such cases, for slight surface irregularities, Industrial Grade pads can be provided by Armadillo NV as an alternative low cost solution.

Vibstop

Vibstop isolation material is a specifically designed vibration absorbing medium. Produced as a cost-effective solution to isolating foundations whether it be existing machinery or installing new equipment.

Armacush

Armadillo Armacush is an ideal product which not only gives excellent long term performance but is also specifically designed for ease of installation to avoid costly delays in the construction process. Designed for full area coverage the problem of temporary shuttering or designing the mass to be able to span bearing centres is avoided.